-

Help you save cost and time.

Help you save cost and time. -

Provide reliable packaging for your goods.

Provide reliable packaging for your goods. -

Fast and reliable delivery to save time.

Fast and reliable delivery to save time. -

Excellent after-sales service.

Excellent after-sales service.

Industrial parts

Blog

Post

part number

Popular parts

Latest parts

-

MAX3232CPWR

-

74HC123PW

-

SN74HC126PW

-

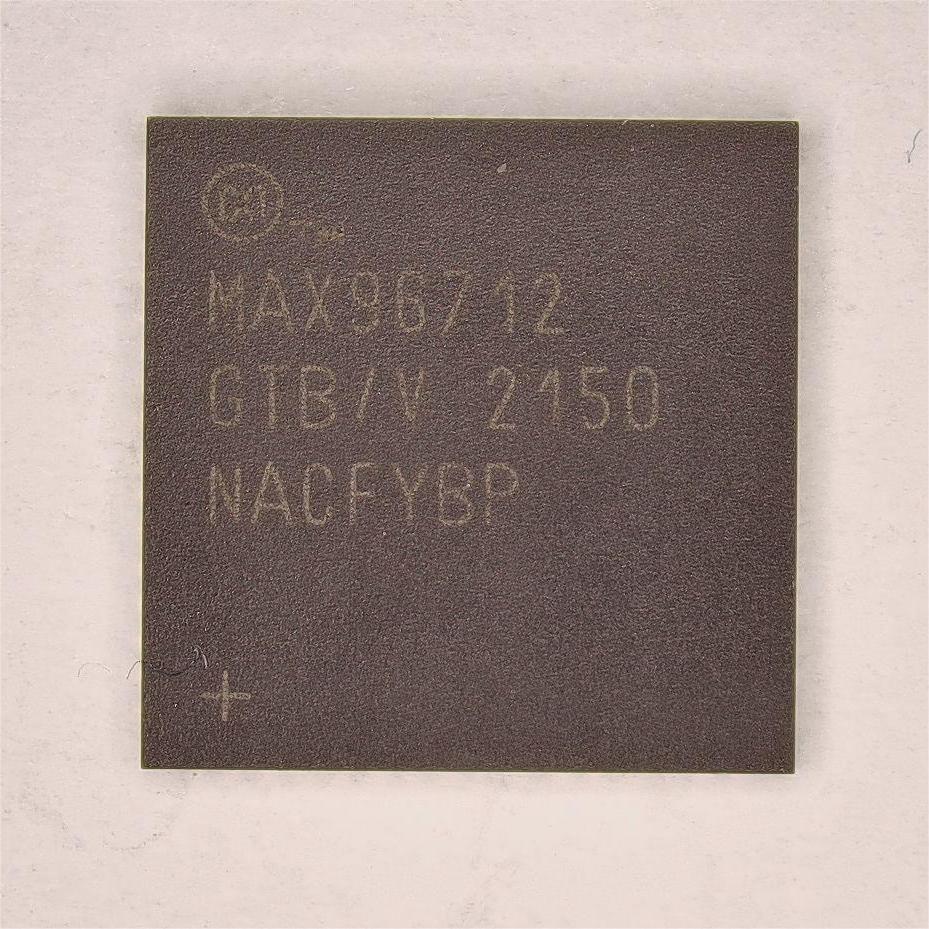

MAX96712GTBV+T

-

ADS1015IDGSR

-

88SE9235A1-NAA2C000

-

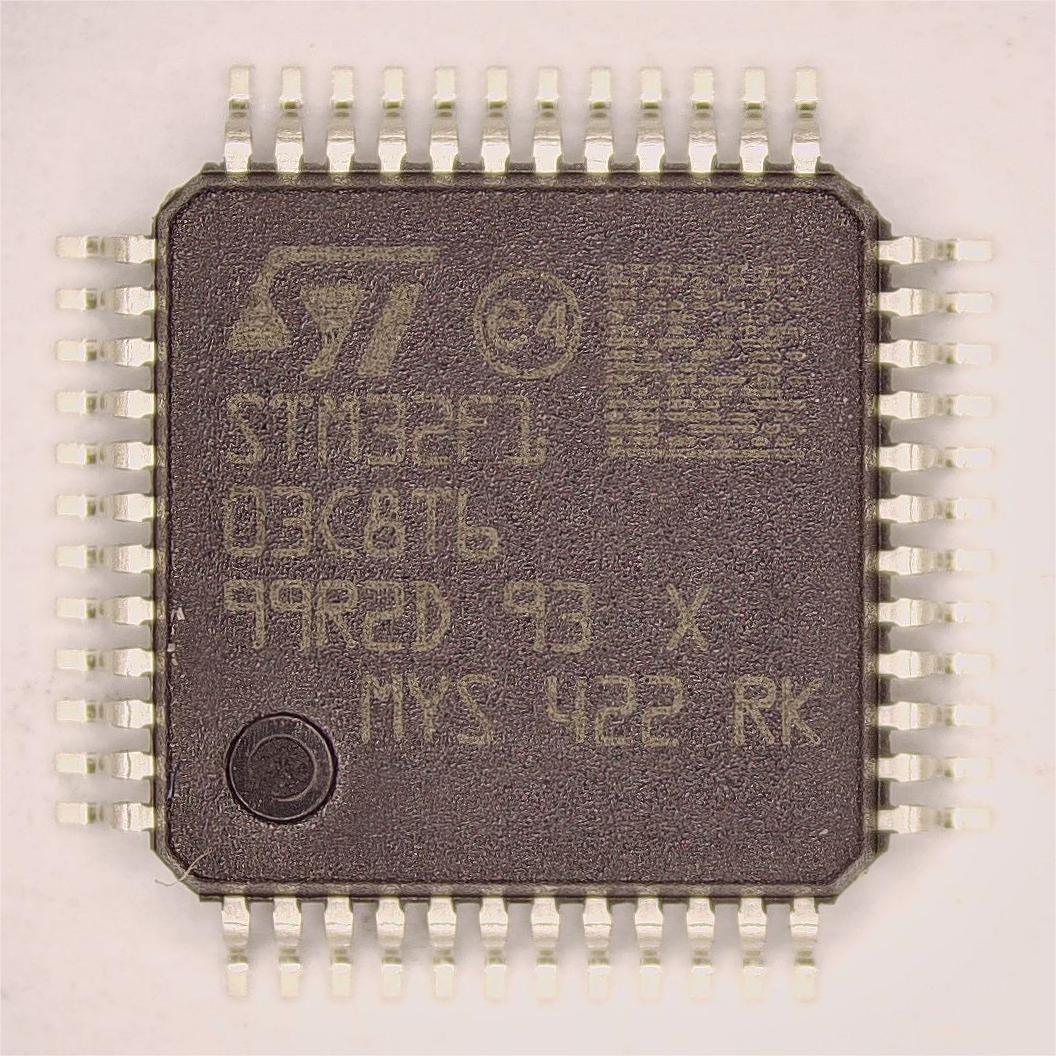

STM32F103C8T6

-

ADSP-21489BSWZ-4B

-

AD7606BSTZ

-

S432SYGWA/S530-E2

-

HMC1060LP3ETR

-

HMC833LP6GETR

-

LTM8023IY#PBF

-

LT3800EFE#PBF

-

MBR0540T1G

-

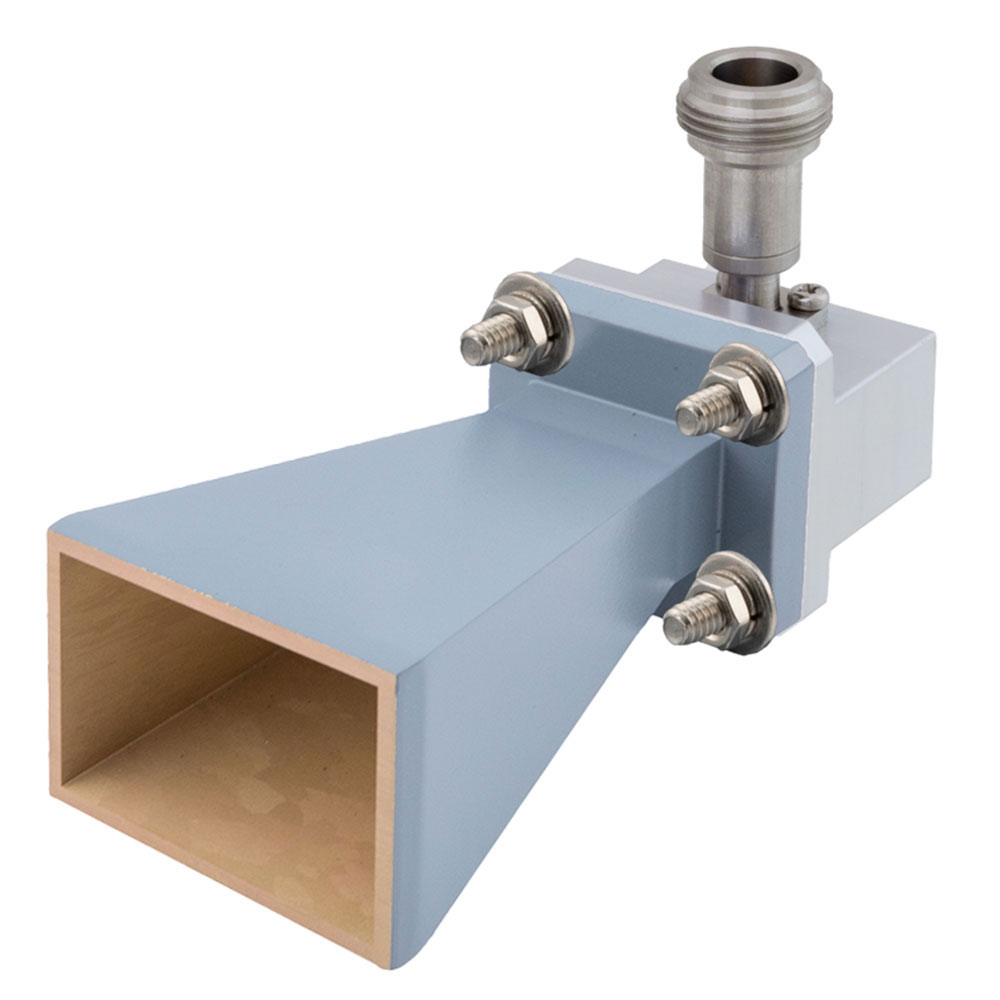

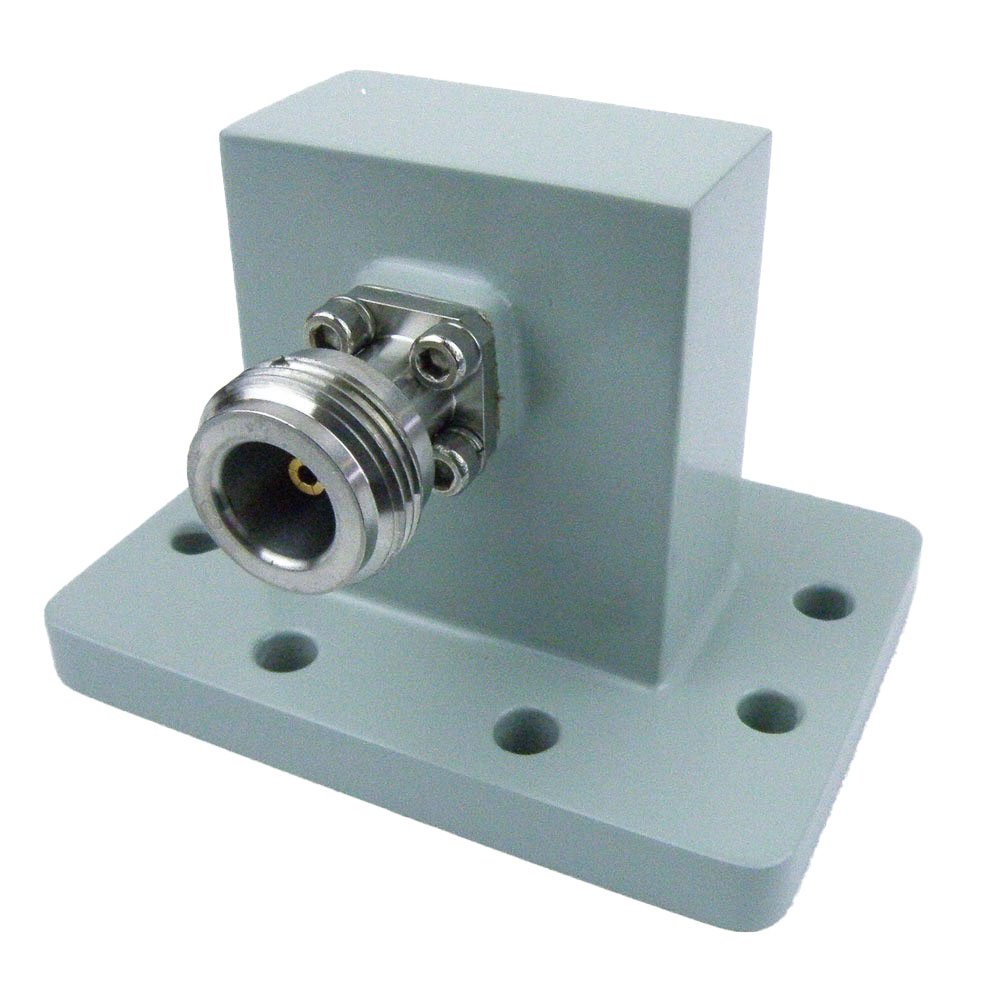

FMWAN062-15NF

-

FMAT7483-10

-

SMW137ACN

-

FMSW6252

-

FMCP1139-30

-

SMW28TF005-12

-

SA18S100-30

-

DSC1211NE3-C0021T

-

FM9855B-10

-

SA18NFNF50W-40

-

CHV1812N2K0471JCT

-

SDUS-0518-SPDT-SMA

-

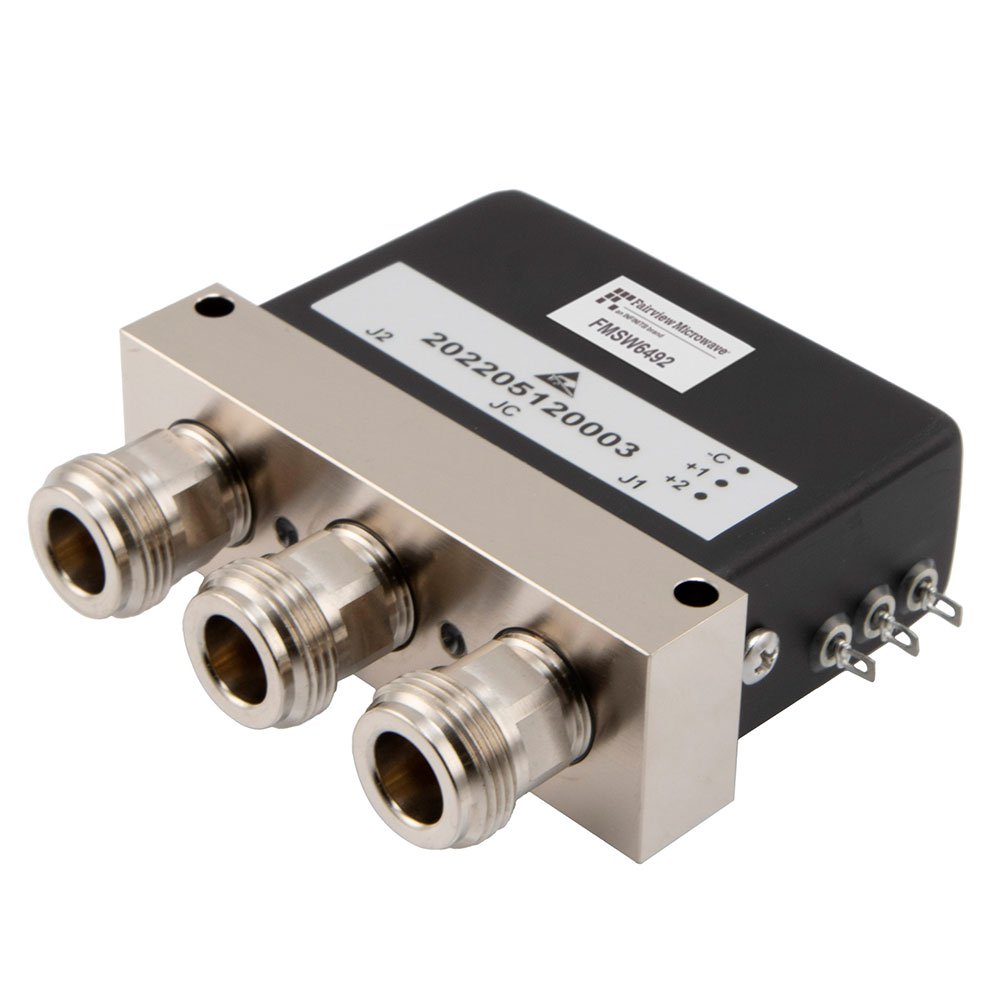

FMSW6492

-

SA18TMTF25W-20

-

CHV1812N250223KXT